Water-cooled Screw Chiller

Description:

The high-efficiency water-cooled screw chiller is designed with advanced semi-enclosed dual-screw compressor, R134a eco-friendly refrigerant and vertical oil separator, making this chiller with stable performance, high efficiency, and energy saving.

The amount of steam generated in the evaporator of the screw chiller is large, and the heat dissipation area is also large, which makes the cooling effect better. Its cooling capacity and energy efficiency ratio can be guaranteed. At the same time, it has low noise, low vibration, easy installation, and low requirements for equipment.

Application:

This water-cooled screw chiller can be used as the cooling system for large commercial buildings, office buildings, factories, power plants, chemical plants, steel plants, hospitals, schools, shopping centers and production processing.

Features:

1. Semi-closed Dual Screw Compressor for High-efficiency Unit

● This compressor is designed for the water-cooled screw chiller according to actual pressure ratio, with good matching, reducing the over compression and insufficient compressor during the operation of compressor, thus enhancing system energy efficiency.

● Self-developed efficient rotor type line (patent No.: CN201120008270.9), interdigitating gap is optimized, connection cable is short and the efficiency is even higher.

● Three-level combined built-in oil separator, the efficiency is over 99.7%, making the system more stable with less noise.

● The closed motor to avoid refrigerant leakage, built-in PTC temperature protector for the motor, effectively detect motor winding temperature.

2. Flooded-type Evaporator

Refrigerant is evenly distributed in the evaporator. With a flooded type evaporator, evaporation temperature is increased and so is the heat exchange efficiency. Together with a screw compressor that is specialized for flooded type chiller, the unit’s cooling capacity and energy efficiency ratio is greatly improved. COP can reach 6.2.2.

3. Reliable Oil Return

With the patented high-efficiency oil separator and injection-type oil return, the unit can still achieve reliable oil return even when it is running under poor working conditions. The unit is designed with low oil protection to avoid compressor damage caused by oil shortages.

4. Stepless Adjustment

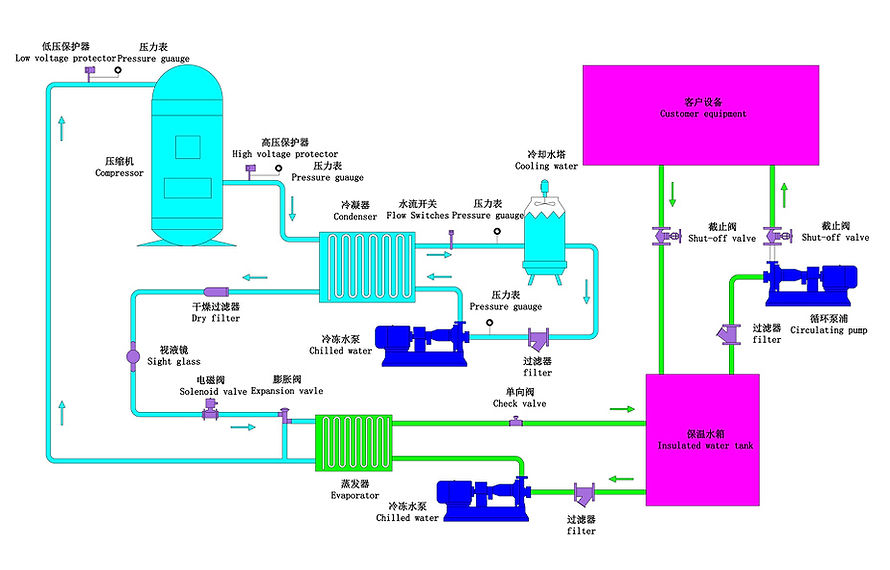

Structure and Working Principle:

The screw chiller is composed of a screw compressor, a condenser, an evaporator, a throttle valve, etc. Among them, the screw compressor is its core component, which is composed of two screws tightly coupled. The screw runs inside to create high-pressure air, which releases heat after entering the condenser and discharges high-temperature and high-pressure steam. Then the steam flows into the throttle valve, reduces the pressure and passes through the evaporator. It absorbs heat and cools down, becomes low-temperature and low-pressure steam and returns to the compressor. The cycle is compressed again to form cold water.